Introduction

The subject of this Operation Management report is the Toyota Manufacturing Plant in Karawang, a plant owned by PT. Toyota Motor Manufacturing Indonesia (TMMIN). The analysis of Toyota Manufacturing Plant in Karawang is used to understand Toyota Production System (TPS), especially Lean Manufacturing System and Built in Quality Management. These factors are why Toyota has highest market share and becoming market dominant in Indonesian automobile market. Finally, in accordance with TPS policy of constant improvement (Kaizen), there is an outline of what the company’s current and potential problems in operation are perceived to be and recommendations of how TMMIN can overcome them.

Organization Profile

Toyota Motor Corporation (TMC) is a multinational corporation headquartered in Japan. It is the world’s largest automotive manufacturer by sales and production (Marr, 2009). In 2009, TMC employed 71,116 people worldwide (Toyota Motor Corporation 2010a). TMC is headquartered in Toyota City, Aichi and in Tokyo. Its revenues in 2010 (March) globally reached 18.9 trillion Yen (Toyota Motor Corporation, 2010b).

TMC started its business in Indonesia by doing joint venture with Astra by establishing PT. Toyota-Astra Motor (TAM) in 1971. The role of TAM was originally only as an importer of Toyota vehicles, but a year later was working as a distributor. On December 31st, 1989, TAM did merger with three companies among others, which are PT. Astra Multi, PT. Toyota Mobilindo, PT. Toyota Engine Indonesia and still hold the same name as TAM. The merger was done to unify measures and efficiency in increasing quality and facing competition in the automotive industry (Toyota Astra Motor, 2007a).

TAM restructured into two companies in 2003 became PT. Toyota Motor Manufacturing Indonesia (TMMIN) and PT. Toyota-Astra Motor (TAM). TMMIN fabricates and exports Toyota vehicles and spare parts. The composition of stock ownership in TMMIN is Astra International was 5% and 95% TMC. TAM operates as sales agent, importer, and distributor of Toyota products in Indonesia. The composition of stock ownership in TAM is Astra International is 51% while 49% TMC (Toyota Astra Motor, 2007a).

TAM has five primary dealer to support its sales and after sales service for all over Indonesia. These primary dealers are divided according to geographical region. Auto2000 is the Toyota Main Dealer in the Jakarta, West Java, East Java, East Nusa Tenggara, Bali, Kalimantan and partly Sumatra. PT. New Ratna Toyota Motor is a Primary Dealer in the region Central Java and Yogyakarta. NV Hadji Kalla Trd Co. is a Toyota Main Dealer in the region South Sulawesi and Southeast Sulawesi. PT. Hasjrat Abadi is a Toyota Main Dealer in the region North Sulawesi, Central Sulawesi, Gorontalo, Moluccas, Ternate and Papua. PT Agung Automall is a Toyota Main Dealer in the region Bali, Riau, Jambi, Bengkulu, and Batam (Toyota Astra Motor, 2007a).

TMMIN has two production plants, which are Sunter Plant and Karawang Plant. Sunter Plant was built in April 1973, located in Sunter, North Jakarta. It is the first automobile factory owned by TMMIN, which has a concept of combining modern technology and human resources expertise. The plant produces part component and machine for domestic and export market. Sunter Plant has facilities consist of Casting Plant, Stamping Plant, Engine Plant, Packing & Vanning Plant, and Waste Water Treatment (Toyota Astra Motor, 2007b).

Karawang Plant is newest of the automobile factory owned by TMMIN. It is located in Karawang International Industrial City (KIIC), Teluk Jambe, West Java. Karawang Plant was built in 1996 and began operating in 1998. It has facilities consist of Stamping Shop, Welding Shop, Painting Shop, Assembling Shop, Test Course, Common Yard, and Environment Management System. Nowadays, Karawang Plant has production capacity of 100,000 units of cars per year (Toyota Astra Motor, 2007c).

Karawang Plant has a concept of world class automotive manufacturer which combines high technology, human resources expertise, and concern for employees and environment. It is built on 1.000.000 m2 of land with building area of 300,000 m2. Karawang Plant focuses on manufacturing of Innova, Avanza G Black, and Fortuner for domestic and international markets. Its products are exported to Middle Eastern countries (Saudi Arabia, United Arab Emirates, Kuwait, Bahrain, Qatar, Oman, Jordan, Syria, and Lebanon), Pacific Island countries (Fiji and Solomon), and the Asian countries (Malaysia, Philippines, Brunei Darussalam, Thailand, and Vietnam) (Toyota Astra Motor, 2007c).

General Flow Process

According to Jacob, Chase, and Aquilano (2009), process is any part of an organization that takes inputs and transforms them into outputs that are of greater value to the organization than the original input. Karawang plant’s processes are done in some in-house production facilities, which are stamping shop, welding shop, painting shop, and assembling shop.

Car production is started at stamping shop. It is where the body parts of vehicle are stamped or pressed out of the steel plates. Stamping shop has two lines, which are A line with capacity of 2400 tons and 450 strokes/hour and C line with capacity of 700 tons with 620 strokes/hour. The input for stamping process is steel plates. The process starts at one row of press where steel sheet are cut from coil and fed into the first press. After that, it is routed to the next presses where the press may create the curved shape. From there, it is passed to a press that punches holes until finally the finished part rolls off the press line. The process in stamp shop uses robotic system to move pressed parts between machines. The output of stamping shop are the frame, fuel tank, and some components, such as cabin, deck, and frame chassis (Toyota Astra Motor, 2007d).

Welding shop does joining/welding of subgroups or smaller car body units into one part intact. The input for welding process is pressed body parts from stamping shop. The process unifies all the pressed parts. The end result of this process is a completed body shell. To ensure the level of precision and high accuracy, welding shop is equipped with Welding Main Body Line, Coordinate Measuring Machine, and Shell Body Line with Slat Conveyor. Welding shop is also supported with 34 welding robots and global body line (Toyota Astra Motor, 2007e).

Paint shop takes car bodies from the welding shop and applies color to the vehicle. The shop consists of multiple paint booths that are use robots to spray-paint the body shell coming from the welding shop. The body sell are dipped in a electro deeping coating that cover the body with anti rust coating. Then they are organized by color and sent to one of the paint booths. Some colors will require multiple coats which will result in the vehicles getting out of the plan line-off sequence. Painting shop has a painting facility which is Primer and Top Coat process with robotic systems to obtain results of high-quality paint. It also uses twenty robots to provide security guarantees and environmentally friendly process (Toyota Astra Motor, 2007f).

Assembling shop is a place of assembly of the whole vehicle body into a complete vehicle ready for the road. Assembly process is to install all components of the vehicle into vehicle body coming from paint shop. The assembly shop is the most labor intensive shop. Most of the components are installed by hand by team members working in small team. Each team is responsible for the work perform during one process cycle at one work station. The vehicles thus move from one station to the next at the takt time interval. Takt is a German word for rhythm or meter which means the rate of customer demand (Iyer, Seshadri, and Vasher, 2009). The assembling shop has Main Line Assembly facilities with door less system assembly which guarantees quality and increases productivity. It is also equipped with Final Test Facility, which check each vehicle to ensure quality (Toyota Astra Motor, 2007g).

Potential Problems and Recommendation

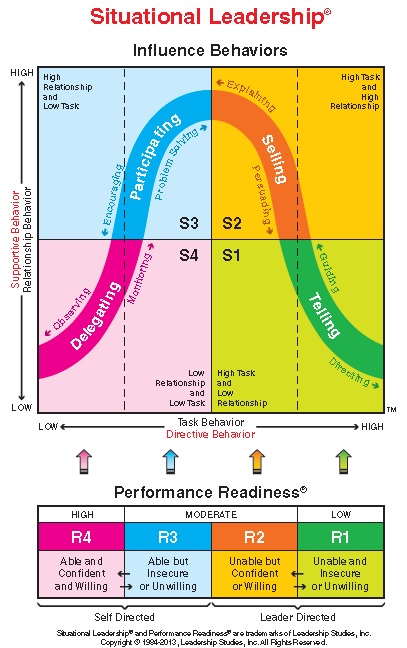

TMMIN has implemented Toyota Production System (TPS) in Karawang plant. TPS is an integrated system developed by Toyota that comprises its management philosophy and practices. The main objectives of TPS are to design out overburden (muri) and inconsistency (mura), and to eliminate waste (muda). There are then two outer pillars in TPS, which are Just-in-time and Jidoka.

Just-in-Time means making only what is needed, when it is needed, and in the amount needed. Supplying Just-in-Time according to production plan can eliminate waste, inconsistencies, and unreasonable requirements, resulting in improved productivity. Just-in-Time tries to constantly improve manufacturing processes to require fewer inventories. Just-in-Time process relies on Kanban between different processes. This will instruct production when to make the next part. Kanban can be simple visual signals such as tickets or just the signal of presence or absence of a part on a shelf (Toyota Motor Corporation, 2010c).

Jidoka can be defined as automation with a human touch. It refers to the practice of stopping a manual line or process when something goes wrong (Toyota Motor Corporation, 2010d). Jidoka can also be defined as the decision to stop and fix problems as they occur as opposed to pushing them down the line to be resolved later. Therefore, purpose of Jidoka is to have immediate identification and correction of mistakes that occur in a process (Liker, 2004). Jidoka makes labor no longer be needed to always have attention whether the process is normal or not. The labor are needed when there is a problem alerted by the machine. Therefore, the quality control has already built in the process. Further, by practicing Jidoka, operator could be put in charge of numerous tasks but still maintaining quality, and therefore resulting in improvement in productivity.

![clip_image007[4] clip_image007[4]](https://livingmba.files.wordpress.com/2011/01/clip_image0074_thumb.jpg?w=609&h=532)

TPS has successfully brought Toyota to have highest market share and to become market dominant in Indonesian automobile market. In accordance with TPS policy of constant improvement (Kaizen), we identify some potential problems could happened in implementing TPS. We categorize these potential problem based on function in the company such as Purchasing, Production, and Marketing.

Purchasing

In purchasing process, Toyota has its strong reputation in building good relationship with its suppliers. Toyota involves its suppliers in the early stages of the design making. It also share its planned production data to its suppliers, so the suppliers can estimate their own targeted production, the amount of investment they are needed to achieved their targeted production. As the second biggest automobile manufacturer, no doubt that the huge amount cars order mean also a big order of parts too to its suppliers. Toyota also commits to pay the entire bill to its vendor on time, so the supplier will always be having good liquidity ratios. Annually, Toyota held awards for its supplier for those who has superior achievement in quality, delivery and ability to perform Kaizen.

These good reputations of commitment lead to trust on its suppliers. Getting continuous order, good partnership from planning to production, commitment on payment and support in continuous improvement inside the supplier’s manufactures, and also lesson learn of just-in-time in the first and second tier supplier will be a magnitude for the suppliers to make business with Toyota.

With many suppliers around the world, and few demand from automobile makers including Toyota, makes Toyota has stronger bargaining position on its suppliers. But those good things can become potential problems. If Toyota able to maintain good reputation of managing supplier, good commitments to their stake holders, and also can keep their position as one of the biggest car manufacturer in the world, it means that all the tier suppliers that support Toyota will still receive big amount of orders, and other stakeholders who get benefit will support the TPS. But in case of changes such as unpopular rules and policies can make the stakeholders uncomforted and begin not supporting TPS (as an example, payment method changed rules will make supplier late to receive their payment, unpopular employee rules, can make a strike). This potential problem can affect to the production. To anticipate this, Toyota has to analyze all the condition that might happen because of this changing before launching a new policies or rules.

Production

In the production, there are some potential problems that can occur. Parts coming from supplier are directly used for production without quality control in Toyota plant. Toyota reduces production time by remove internal quality control at the process and put the material directly to production line. There is a potential problem in this process as if there is some defect in the material; it will only be detected in the final quality control process in the end of assembly shop. This will require a rework to the products which has defect material. If material quality control from supplier is done when material comes to Toyota, we can eliminate the defect material earlier and complain this to supplier to get replacement soon. To anticipate this, Toyota has to train its labor practical quality control internally to do visual inspection on material from the very beginning of the process.

Also in the production, about 70% of the process in assembly shop is done by human. Therefore, labor is a crucial factor to determine successful process. If labor does not have enough knowledge and skill, it would be a problem on the production line. Operators mostly graduated from senior high school, and those operators should have intensive training before they work in the production line. Intensive training are very highly cost and time consuming. There is also wide variety of knowledge and skill level among new recruits in Indonesia. This will be a potential problem if some trainees do not fulfill the minimum standard requirement even after the intensive training. To anticipate this, Toyota has to choose high school graduates from school which has good reputation. Further, Toyota can start its own high school to get standardized curriculum for its new recruits.

Infrastructure in Indonesia is not reliable. Problems such as electricity down, water problem, traffic jam will affect just-in-time process. On the other hand, machinery or robotic down, information system error, and mismatch sequential could be happened in any points of just-in-time production. The other potential problem is that the Toyota production line has only one line which related to every activity. If a process in a station delayed, it will cause delay to other station. To anticipate this, backup system should be considered to prevent production stop.

Marketing

Automotive industry in Indonesia is very dynamic. The market is often fluctuating, responding market trends. The amino in Indonesian market for Toyota cars is many times unpredictable. Some Toyota cars get suddenly high demand. For example, market demand for Avanza product was unpredictably high because sudden demand of low cost family car. Some customers should wait indent for one whole year to get his/her new Avanza. When this situation happened, production line cannot respond quickly because of limited capacity and minimum inventory. To expand capacity quickly means to extend the production line, labor overtime and sudden extra material order to suppliers. This unplanned sudden capacity expansion will put inefficient cost. To anticipate this, market intelligence in Toyota Production System should have a really precise market research to evaluate and determine the trend in the longer period of future time compared to other system.

Since TPS has only one production line, all variant should put together in the line. This will limit Toyota flexibility to produce various or customized product. Modification in the production line is difficult because it changes many processes. These changes will need consideration, how long takt time will be raised because of additional process. Modification will also cost massive training to all labor operated in the line to put more tasks on one worker. The changes will also depend on the flexibility of some limited suppliers which has already adopted TPS system. If these suppliers cannot change their process, Toyota cannot change its process as well. To anticipate longer takt time because of variants addition, Toyota should consider extra line for some new variant, especially if the variant is very different with other variants. To anticipate costly massive training, Toyota should have efficient training center to maintain cost. Further, Toyota should put curriculum for wide variation process if it starts its own dedicated high school. To anticipate Toyota production limited flexibility, Toyota should add more suppliers which implement TPS to anticipate market fluctuation.

Conclusion

· Toyota Production System (TPS) has been implemented in TMMIN Karawang plant by implementing Just-in-time and Jidoka.

· By implementing TPS, TMMIN has several advantages: less waste, inconsistencies, and unreasonable requirements, resulting in improved productivity, and built in quality.

· However, several features of TPS limit TMMIN itself, such as requirement to be in stronger bargaining position and tight payment schedule to suppliers. Also, TMMIN must depend on supplier performance to guarantee its own production objectives.

· Internally, TMMIN needs high standard to labor knowledge and skill. Furthermore, Toyota should start its own dedicated high school to get higher labor knowledge and skill.

· Unreliable infrastructures in Indonesia makes TMMIN should have more back-up system compared to any other plants in other countries.

· To anticipate market fluctuation, TMMIN market intelligence should have precise research to evaluate the trend.

· To anticipate wider variants, TMMIN should invest extra production lines and moreover efficient training center to maintain training costs. To anticipate production limited flexibility, Toyota should add more suppliers which implement TPS.

References

Iyer, A., Seshadri, S., Vasher, R., 2009. Toyota Supply Chain Management: A Strategic Approach to Toyota’s Renowned System. New York: McGraw-Hill

Jacobs, F.R., Chase, R.B., and Aquilano, N.J., 2009. Operation and Supply Management. 12th. ed. New York: McGraw-Hill/Irwin

Liker, J., 2004. The Toyota Way. New York: McGraw-Hill

Marr, K., 2009. Toyota Passes General Motors As World’s Largest Carmaker, [online] Available at: <http://www.washingtonpost.com/wp-dyn/content/article/2009/01/21/AR2009012101216.html> [Accessed 18 November 2010]

Toyota Motor Corporation, 2010a. Toyota in The World 2010. [online] Available at: <http://www2.toyota.co.jp/en/about_toyota/in_the_world/pdf2010/databook_en_2010.pdf> [Accessed 18 November 2010]

Toyota Motor Corporation, 2010b. Financial Summary FY2010: Toyota Motor Company, [online] Available at: <http://www.toyota.co.jp/en/ir/financial_results/2010/year_end/summary.pdf> [Accessed 18 November 2010].

Toyota Motor Corporation, 2010c. Toyota Production System: Just in Time, [online] Available at: <http://www2.toyota.co.jp/en/vision/production_system/just.html> [Accessed 18 November 2010].

Toyota Motor Corporation, 2010d. Toyota Production System: Jidoka, [online] Available at: <http://www2.toyota.co.jp/en/vision/production_system/jidoka.html> [Accessed 18 November 2010].

Toyota Astra Motor, 2007a. Toyota di Indonesia – Profil, [online] Available at: <http://www.toyota.astra.co.id/company/about/profile/ > [Accessed 18 November 2010].

Toyota Astra Motor, 2007b. Toyota di Indonesia – Manufaktur: Sunter Plant, [online] Available at: <http://www.toyota.co.id/company/about/manufacturing/sunter/> [Accessed 18 November 2010].

Toyota Astra Motor, 2007c. Toyota di Indonesia – Manufaktur: Karawang Plant, [online] Available at: <http://www.toyota.co.id/company/about/manufacturing/karawang/> [Accessed 18 November 2010].

Toyota Astra Motor, 2007d. Toyota di Indonesia – Manufaktur: Stamping Shop, [online] Available at: <http://www.toyota.co.id/company/about/manufacturing/karawang/article.php?article_id=1954> [Accessed 18 November 2010].

Toyota Astra Motor, 2007e. Toyota di Indonesia – Manufaktur: Welding Shop, [online] Available at: <http://www.toyota.co.id/company/about/manufacturing/karawang/article.php?article_id=1953> [Accessed 18 November 2010].

Toyota Astra Motor, 2007f. Toyota di Indonesia – Manufaktur: Painting Shop, [online] Available at: <http://www.toyota.co.id/company/about/manufacturing/karawang/article.php?article_id=1952> [Accessed 18 November 2010].

Toyota Astra Motor, 2007g. Toyota di Indonesia – Manufaktur: Assembly Shop, [online] Available at: < http://www.toyota.co.id/company/about/manufacturing/karawang/article.php?article_id=1951> [Accessed 18 November 2010].

![clip_image007[4] clip_image007[4]](https://livingmba.files.wordpress.com/2011/01/clip_image0074_thumb.jpg?w=609&h=532)